When people think about walk-in coolers and freezers, they usually focus on the refrigeration system. It’s understandable since you hear it, you see it, and you notice when it fails. But the truth is simple: the real work happens in the wall panels.

If the panels aren’t built right, nothing else in your walk-in will perform the way you expect. Temperature control slips, energy costs spike, and equipment works overtime just to keep up.

For any operation that relies on safe, consistent cold storage, panel quality is the foundation of walk-in performance.

What Wall Panels Actually Do

Walk-in wall panels create an insulated barrier that separates the inside temperature from the outside environment. They’re responsible for reducing heat transfer, maintaining internal stability, and preventing your refrigeration system from constantly cycling.

Because wall panels make up most of the walk-in’s surface area and face the most exposure to ambient temperatures, they’re often the single most important factor in long-term performance.

The Anatomy of a High-Quality Wall Panel

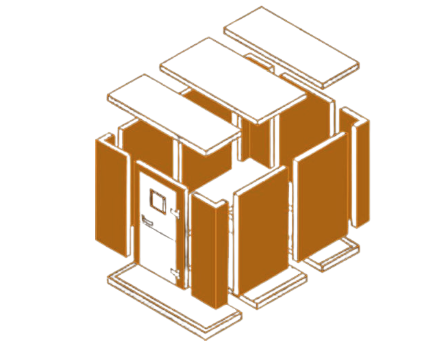

Wall panels are essentially insulation sandwiches: a rigid foam core bonded between sheets of metal. But not all panel construction is equal. The differences in materials, density, and joinery dramatically affect performance and operational costs.

Foamed-In-Place Insulation

Arctic panels use foamed-in-place insulation, which expands to fill every crevice inside the panel. This eliminates air pockets and creates uniform thermal resistance throughout. It’s more consistent and more durable than laminated or board-insert alternatives.

High-Density Foam Core

Arctic offers 4” and 5-3/8” thick high-density insulation, engineered to minimize temperature loss and increase thermal efficiency. The higher the density, the better the structural integrity and long-term performance.

Metal Skins

The metal exteriors protect the foam, provide structural strength, and offer a food-safe surface. The skins must resist moisture, corrosion, and daily wear, especially in high-use commercial environments.

R-Value: The Non-Negotiable Metric of Panel Performance

R-value measures how effectively a panel resists heat flow. Higher R-values slow the transfer of heat from the outside to the inside, reducing the load on the refrigeration system.

Regulatory minimums make the baseline clear:

- R-25 for coolers

- R-32 for freezers

Better R-values mean:

- More stable internal temperatures

- Lower energy costs

- Longer equipment lifespan

- Improved product safety

- Stronger compliance with health and building regulations

Higher R-value panels often cost more upfront, but they save operators significantly more over the life of the walk-in.

What Sets Arctic Walk-Ins Panels Apart

Arctic’s wall panels are built for long-term performance, consistent cold retention, and smooth installation, and our manufacturing process includes several quality steps most competitors simply don’t take.

Manufactured in the USA

Built domestically for stronger quality control, reliable material sourcing, and consistent panel performance.

Foamed-In-Place, High-Density Insulation

Arctic uses 100% foamed-in-place insulation that expands inside the panel, eliminating voids and creating uniform thermal resistance. This outperforms laminated or board-insert panels used by many competitors.

Precision Modular Construction

Tongue-and-groove edges, integral camlocks, and NSF-certified wrap-around gaskets lock panels tightly together to minimize air infiltration and ensure a rigid, sanitary structure.

In-House Assembly & Inspection Before Shipping

Every walk-in is fully assembled on our factory floor to verify panel fit, gasket compression, door alignment, and structural integrity before it ever leaves the building; something most manufacturers never do.

Photo Documentation & QA Records

Arctic photographs each assembled walk-in and keeps detailed quality assurance documentation on file, giving operators traceable proof that their unit has been inspected and verified.

Certified for Commercial Safety and Compliance

Panels meet or exceed major commercial standards, including NSF 7, UL 471, and ASTM E84 / UL 723, ensuring safe use in kitchens, foodservice operations, and other regulated environments.

Myth vs. Reality: What People Get Wrong About Walk-In Wall Panels

Myth 1: “All walk-in panels perform about the same.”

Reality: Panel construction varies widely. Differences in foam density, joinery, and R-value create massive differences in energy usage and long-term performance.

Myth 2: “The refrigeration system is the most important part.”

Reality: The best refrigeration system in the world can’t compensate for weak, leaky, or low-R-value wall panels.

Myth 3: “Panel thickness alone tells you how good the insulation is.”

Reality: Thickness matters, but density, foam quality, and the absence of air pockets matter more.

Myth 4: “If the walk-in holds temp during install, the panels must be good.”

Reality: Early performance proves nothing. Poor panels most often fail one to three years later through moisture intrusion, heat seep, or structural bowing.

Why Wall Panels Fail (and What It Costs You)

Understanding common failure points helps operators recognize why panel quality is worth the investment.

1. Moisture Intrusion

Water is the enemy of insulation. Once foam absorbs moisture, R-value drops and energy usage spikes.

2. Weak or Cheap Camlocks

If the panels can’t lock tightly, air leaks develop, and the refrigeration system ends up running nonstop.

3. Low-Density or Poor-Quality Foam

Cheaper foam compresses over time, reducing insulation and causing the panels to warp or lose structural strength.

4. Delamination

Panels that aren’t foamed-in-place can eventually separate from their metal skins, creating gaps and dead zones.

5. Poor Gasket Design

A bad gasket or poor fit allows warm air inside, creating ice buildup and temperature swings.

These failures don’t just cost money. They undermine product safety and force equipment to work harder than it was designed to.

How to Evaluate Walk-In Wall Panels Before You Buy

Here’s a simple checklist operators, chefs, and facility managers can use:

- What’s the R-value, and does it meet code?

- Is the insulation foamed-in-place or laminated?

- Are multiple panel thickness options available?

- Does the panel have required UL/NSF certifications?

- What is the foam density, and how uniform is the fill?

- What type of locking system does it use?

- How airtight is the gasket and joinery?

- Are materials food-safe, durable, and corrosion-resistant?

- What warranty or service support is offered?

A few minutes of evaluation can prevent years of headaches.

Why Panel Quality Drives Overall Walk-In Performance

When you invest in high-quality wall panels, you’re investing in:

- Consistent temperature control

- Lower energy costs

- Fewer equipment failures

- Longer walk-in lifespan

- Protection for food and product inventory

- Regulatory compliance

- Peace of mind

Everything in your walk-in hinges on the walls’ ability to keep cold where it belongs.

Wall panels aren’t the flashiest part of a walk-in, but they’re the most important. They determine how efficiently the unit runs, how long it lasts, and how well it protects your inventory.

If you want long-term performance, energy efficiency, and reliable temperature stability, start with the panels. Everything else depends on them.

Explore Arctic Walk-Ins’ high-quality wall panel options or talk with our team to find the right configuration for your application.