Walk-in coolers, and the panels that make them work, are an important part of our modern lives. While you may not have paused to reflect on this much before now, it’s true! Maybe you need to safely store some venison you recently processed. Perhaps you need to keep a large delivery of beer crisp before selling it to bar patrons. Somewhere, an organic farmer needs a place to store her cut-flowers until she leaves to sell them at the farmers’ market. In a basement lab, a scientist is making an important discovery and needs to keep test samples at a safe temperature.

It’s not just professionals in specific fields of work that can utilize a walk-in cooler in their daily lives. For some people, a walk-in cooler in your home can make a lot of sense.

Whatever your needs, it can be an intimidatingly industrial endeavor to undertake – though it doesn’t need to be. Today, we’ll take a step towards demystifying the process by diving into the world of walk-in cooler panels: what are these panels, and how do they work?

Panel Basics

A panel is a flat or curved component, that forms or is set into a wall, door, or ceiling. The panels of a walk-in cooler are constructed of insulation situated between the metal “skin.” Most often, companies, manufacturers, and DIY warriors use aluminum, stainless steel, or galvanized steel for this. Without proper and efficient panels, your walk-in cooler wouldn’t stay brisk for long. And while this may seem counter-intuitive to those of us that are new to the world of refrigeration, as it turns out, insulation is just as important for keeping the cool air in as it is for warming your house on a cold winter night.

The layer of insulation inside the metal skin is usually around 4 inches thick and generally consists of high-density foam insulation. This guards your cooler against temperature loss and will increase the efficiency of your unit.

In the early days of walk-in coolers, there were rails around the panel made of wood. Eventually, construction methods advanced and evolved to include the all-foam techniques used today.

Insulation and R-Value

Insulation is a broad term – and there are a lot of ways to interpret it and put it into practice. Ultimately, however it is you plan to incorporate it, you’ll want to make sure that your insulation is of high quality. Efficiency is key.

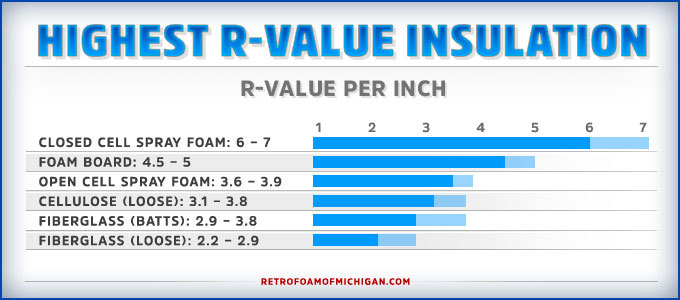

So how do you evaluate efficiency? Well, R-value is how we measure insulation quality. The higher the R-value rating of a certain type of insulation, the greater the effectiveness of that insulation.

Polyurethane

The most common form of insulation material for walk-in coolers (and many many other things) is foam-in polyurethane. It has a very high R-value, so this is no surprise.

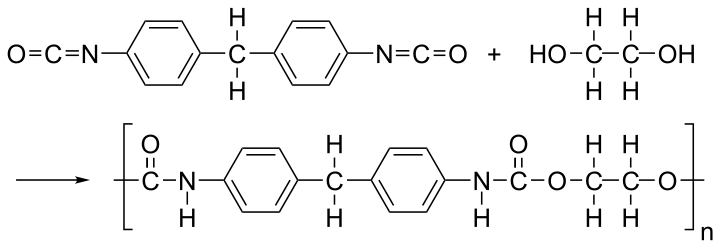

Polyurethane is one of humanity’s most versatile plastic materials because of its adaptability. A quick science dive: polyurethanes are formed by reacting a polyol with a diisocyanate. They are also formed by a polymeric isocyanate in the presence of suitable catalysts and additives. There are a variety of diisocyanates and many polyols that scientists utilize to produce polyurethane. We can shape, cast, and mold this plastic material in ways that add considerable convenience to our lives.

In addition to being used in walk-in cooler panels, polyurethanes are used in roller-blade wheels, mattresses, and paint.

What’s Next?

Panels are just one aspect of how walk-in coolers and freezers function to meet our needs. As you work through what it is you need and want from a walk-in cooler, there are many other elements to consider and decide upon – overall size, exterior finish, and doors to name a few. Thoughtful consideration and research will lead you to make confident decisions in deciding what’s best for your home or business and maintaining it for years to come.