Every walk-in cooler and freezer has an operating cost. But most business owners only see part of the picture.

The monthly electric bill is obvious. What’s less visible are the hidden expenses that quietly drain profit: inefficient equipment, poor insulation, premature failures, and product loss. These costs compound over time, and in many cases, they far exceed the initial purchase price.

Understanding what drives operating costs isn’t just good business practice. It’s essential for making informed purchasing decisions and protecting your bottom line over the long term.

Beyond the Electric Bill: What Actually Costs You Money

Walk-in operating expenses extend far beyond energy consumption. The true cost includes several interconnected factors that affect profitability differently.

Energy consumption represents the most visible ongoing expense, driven by how efficiently your refrigeration system maintains temperature and how well your insulation retains cold.

Maintenance requirements vary dramatically based on equipment quality. Well-built walk-ins need routine service. Poorly built ones demand constant attention and frequent repairs.

Product loss happens when temperature control fails. For operations dealing with perishable inventory, even minor failures carry financial consequences.

Downtime disrupts business operations. When cold storage stops working, everything stops: sales, production, service, and customer satisfaction.

Equipment lifespan determines how soon you’ll face replacement costs. Units forced to work harder wear out faster, accelerating the timeline for major capital expenditures.

Regulatory compliance protects your license to operate. Walk-ins that can’t maintain proper temperatures create legal and reputational risks that go beyond immediate financial impact.

When you account for all these factors, the real cost of operating a walk-in becomes clear, and it’s almost always higher than expected.

The Insulation Factor: Why Panel Quality Controls Everything

Energy costs aren’t fixed. They respond directly to how well your walk-in retains temperature.

Poor insulation forces refrigeration systems to run more frequently, cycling on and off to compensate for heat infiltration. That increased runtime drives energy consumption higher and accelerates component wear.

High-quality panels with proper R-values create a stable thermal barrier that reduces the refrigeration system’s workload. The compressor runs less often, energy usage drops, and equipment lasts longer.

The difference isn’t marginal. Over the lifespan of a walk-in, insulation quality can represent thousands of dollars in energy savings and extended equipment life.

Investing in better panels costs more upfront but pays back through reduced operating expenses. Cheap panels cost less initially but require you to pay the difference, with interest, every month for years.

Maintenance: Predictable Service vs. Emergency Repairs

All walk-ins require maintenance. The question is whether you control the schedule or the schedule controls you.

Routine maintenance keeps equipment running efficiently. Filter changes, coil cleaning, gasket inspections, and refrigerant checks prevent problems before they become failures. This type of service is predictable, affordable, and manageable.

Reactive repairs happen when something breaks. Service calls, emergency technician fees, and component replacements come without warning and always at the worst possible time. These expenses are unpredictable, disruptive, and expensive.

Walk-ins built with quality components and proper construction need less reactive maintenance. Cheap units fail more often, driving service costs higher and creating operational chaos.

The pattern is consistent: operators who invest in quality and perform routine maintenance spend less on repairs over time. Those who buy cheap and defer service pay significantly more through emergency fixes and premature replacement.

Product Loss: The Hidden Expense That Hits Hardest

For businesses that depend on temperature-controlled inventory, product loss isn’t theoretical. It’s a direct hit to profit.

Temperature fluctuations, even minor ones, can compromise product safety or quality. Complete equipment failures can destroy entire inventories in a matter of hours.

The financial impact varies by operation. A restaurant might lose hundreds of dollars in spoiled ingredients. A distributor might face thousands in damaged goods. A pharmaceutical operation could see regulatory action in addition to inventory loss.

Beyond the immediate cost, product loss creates secondary problems: menu limitations, missed deliveries, customer disappointment, and damaged reputation.

Quality walk-ins with reliable temperature control and strong insulation reduce this risk substantially. They’re not just protecting cold air; they’re protecting business assets and operational continuity.

Downtime: When Operations Stop, Money Stops

Walk-in failures don’t just cost repair dollars. They stop business.

Restaurants can’t serve key menu items. Grocery stores pull products from shelves. Distributors scramble to preserve inventory or find emergency storage. Every hour of downtime carries costs that extend beyond the repair bill.

Emergency solutions (rented coolers, temporary relocation, expedited service calls) add expense and complexity. Staff time gets redirected from productive work to crisis management. Customer service suffers.

For some operations, a single extended failure can cost more than the walk-in itself.

The best defense against downtime is prevention: quality construction, reliable components, proper maintenance, and working with manufacturers who support their products over the long term.

Equipment Life: The Long View on Walk-In Investment

Walk-in refrigeration systems can last well over a decade with proper care. But actual lifespan depends heavily on operating conditions and construction quality.

Units forced to work harder than designed wear out faster. Poor insulation, inadequate airflow, excessive door traffic, and deferred maintenance all shorten equipment life.

When a compressor or refrigeration system fails prematurely, replacement becomes a significant unplanned capital expense. The cost isn’t just the equipment; it’s the installation, downtime, and disruption to operations.

High-quality walk-ins extend equipment life by reducing unnecessary strain on components. Better insulation means less frequent cycling. Solid construction means fewer air leaks. Quality manufacturing means components that hold up under commercial use.

The upfront investment in a better walk-in gets distributed across more years of reliable service, lowering the true cost per year of operation.

Return on Investment: Total Cost of Ownership Over Time

Return on investment for walk-in coolers and freezers isn’t measured at the point of purchase. It’s measured over the entire operational lifespan.

A less expensive walk-in might look attractive initially, but higher energy costs, frequent repairs, and shorter equipment life often make it the more expensive choice over time.

A quality walk-in costs more upfront but typically delivers lower energy consumption, reduced maintenance needs, fewer product loss incidents, less downtime, and longer equipment life. Those advantages compound over the years of operation.

Smart operators evaluate the total cost of ownership, not just the purchase price. The cheapest option rarely saves money when you account for operational expenses and replacement timelines.

How to Reduce Walk-In Operating Costs

Several factors within your control can significantly lower operating expenses.

Prioritize insulation quality. High-R-value panels are the foundation of energy efficiency and stable temperature control. Don’t compromise here.

Size refrigeration properly. Systems that are too small work too hard. Systems that are too large cycle inefficiently. Correct sizing optimizes performance and lifespan.

Invest in preventive maintenance. Routine service costs far less than emergency repairs and helps equipment run efficiently longer.

Train staff on best practices. How people use the walk-in affects energy consumption. Minimize door openings, ensure doors close fully, and avoid blocking airflow.

Consider efficiency upgrades. Strip curtains, LED lighting, and modern controls can improve efficiency without major investment.

Work with experienced professionals. Knowledgeable reps and contractors help you choose the right configuration for your specific application and avoid costly mistakes.

Warning Signs Your Walk-In Is Costing More Than It Should

Certain symptoms indicate a walk-in is operating inefficiently and driving up costs:

The compressor runs constantly or cycles too frequently. Temperature varies outside your target range. Ice builds up on walls, ceilings, or coils. Energy bills seem higher than expected. Service calls are becoming more frequent. Doors don’t seal properly or gaskets show wear. Panels show visible damage or moisture intrusion.

Any of these issues signals inefficiency. Addressing them quickly prevents bigger problems and higher costs down the road.

If your walk-in is showing multiple warning signs, it may be time to evaluate whether ongoing operating costs justify replacement with a more efficient unit.

The Real Calculation: Investing in Quality

Walk-in coolers and freezers are critical business assets, not disposable equipment. They protect inventory, support operations, and affect profitability every day they’re in use.

Understanding the true cost of cold storage means looking beyond the purchase price to consider energy efficiency, maintenance requirements, product protection, and equipment longevity.

Quality construction, proper insulation, and reliable components cost more initially but deliver better performance and lower operating expenses over time. The cheapest option typically becomes the most expensive when you add up years of inflated energy bills, frequent repairs, and premature replacement.

For operators serious about controlling costs and maximizing return on investment, the decision is straightforward: invest in quality that performs efficiently for the long term.

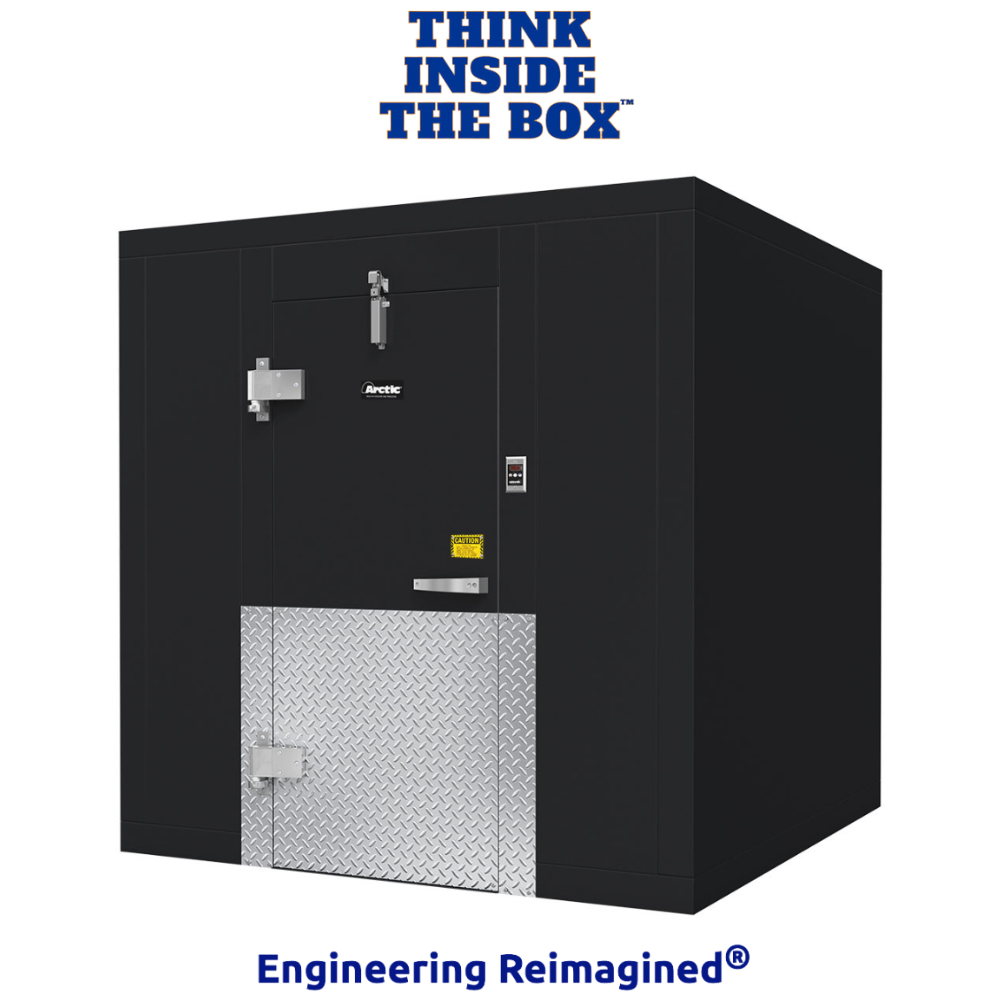

Connect with Arctic Walk-Ins to discuss solutions designed for your specific application and operating conditions.