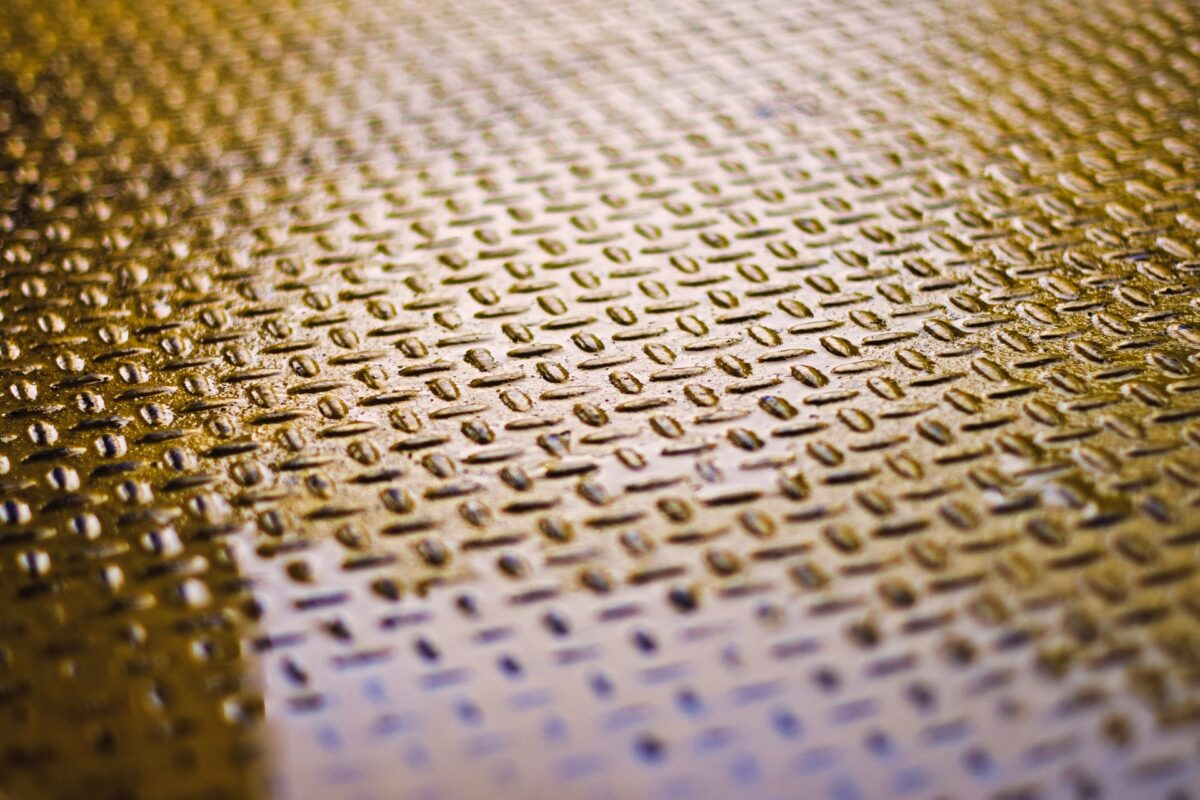

Diamond plates are metal plates with a textured pattern to add traction. Its high durability makes it an extremely practical material for many types of structures in equally as many settings. As you weigh your options for different types of diamond plates, you’ll want to consider the material, the weight, and the aesthetic. Here, we’ve compiled an overview of each of these topics so you know what you’re getting into when buying diamond plates.

What Is Diamond Plate?

Diamond plates are sheet metal with a pattern of raised diamonds perforating the surface. They are also known as tread plates or checkered plates, the added texture provides protection and tread. Because of the added traction, diamond plate is most commonly found on floors, ramps, catwalks, work platforms, and stairs. Slip resistance is key, and many industries have taken advantage of the material. For example, ambulance floors and fire truck steps are classic examples of diamond plates’ usefulness. Overall, diamond plate tread (DPT) is the perfect material for any sector where employees need to efficiently move around in a sanitized environment.

How Is Diamond Plate Made?

To make any sheet metal, the source material is passed through a series of progressively narrowing rollers, until the desired thickness is achieved. To process diamond plates, there are a couple of additional steps, depending on the type of metal. For any material, the last set of rollers is textured to emboss the pattern onto the plate. While aluminum is soft enough to be stamped as is, steel necessitates hot rollers. Once the steal reaches its recrystallization temperature, the shape reforms to the new structure.

Diamond Plate Material

Diamond plates can be made from various metals and rolled to differing thicknesses, depending on their intended use. For the most part, the metals used for DPT include mild steel, stainless steel, and aluminum. Diamond plating can also be imprinted into plastic and rubber for additional tread on plastic sheets and floor mats. Here, we’ve provided an overview of the three most popular DPT materials. In general, all the options are easy to clean and hide scratches and wear, making any of these materials great choices for ramps, floors, doors, or walls.

Aluminum Diamond Plates

Firstly, one of the most popular choices for DPT is aluminum. Light, corrosion-resistant, and often more affordable, aluminum is a versatile choice for indoor and outdoor use. For both flooring and wainscoting, aluminum is popular for walk-in refrigerators and freezers. Because it’s so easily stamped, aluminum diamond plates are often offered in more patterns.

Steel Diamond Plates

Of the available metals, traditional steel is overall the most affordable option. The concentration of carbon will impact the flexibility and durability of the steel. More mild carbonized steel will be easier to work with though less sturdy. On the other hand, highly carbonized steel works better for intensively structured projects, though it’s more challenging to shape. If corrosion is a concern, save steel diamond plates for indoor use. The iron will eventually rust if exposed to water or oxygen.

Stainless Steel Diamond Plates

By far the most expensive option, the stainless steel diamond plate offers both the anti-corrosion elements of aluminum and the strength of steel. If you need a sturdy floor for rolling kegs or wainscotting for an outdoor structure, for instance, stainless steel diamond plate will give you longevity and reliability.

The Big Deal about Stainless Steel

Like other steels, stainless steel is mostly made from iron. However, other elements are key to protecting the material from rust. Of these additives, chromium (or chrome) gives stainless steel its characteristic properties. When iron rusts, the material eventually disintegrates. However, chromium more quickly reacts with oxygen in the air and will rust before iron. When chrome oxidizes, it forms chromium oxide, which acts as a thin layer protecting the iron molecules from the environment. As a result, stainless steel doesn’t rust or corrode, so it sits on a well-deserved pedestal in material science.

Diamond Plate Gauge

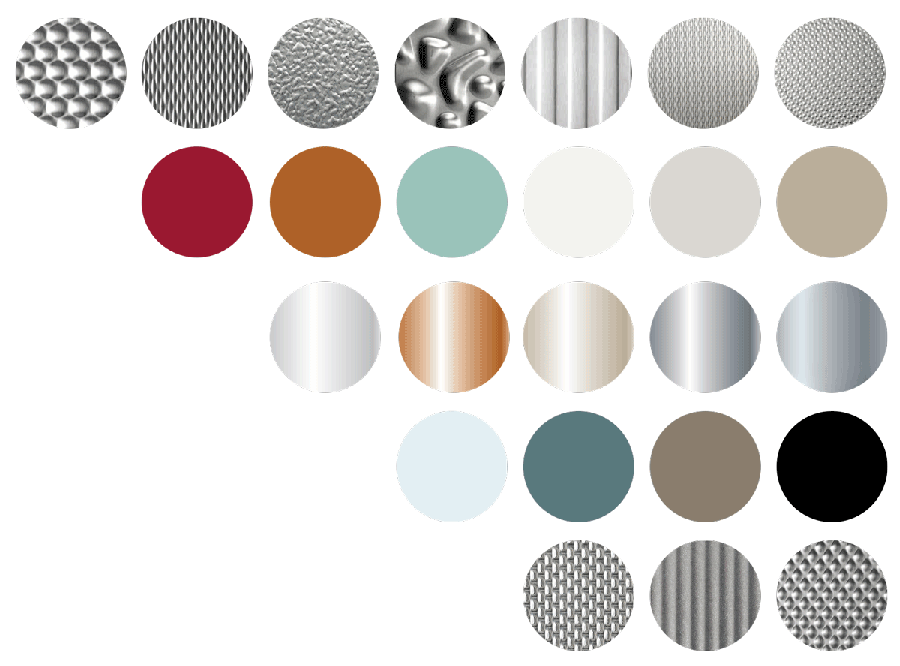

The thickness of sheet metal is measured in fractions of an inch or its gauge. Make sure you understand the specifics of your chosen tread because the gauge corresponds to different thicknesses, depending on the metal. For this reason, refer to the chart below for a comparison of aluminum and steel gauge thicknesses.

| Gauge | Mild Steel Thickness | Stainless Steel Thickness | Aluminum Thickness |

| 22 | 0.029 | 0.031 | 0.025 |

| 20 | 0.036 | 0.037 | 0.032 |

| 18 | 0.048 | 0.050 | 0.040 |

| 16 | 0.060 | 0.062 | 0.051 |

| 14 | 0.075 | 0.078 | 0.064 |

| 12 | 0.105 | 0.109 | 0.081 |

| 10 | 0.134 | 0.141 | 0.102 |

| 8 | 0.164 | 0.172 | 0.128 |

Choosing DPT Thickness

For aluminum walls and wainscotting, choosing a thickness between 0.025-0.032 inches will provide plenty of supple bend for shaping with adequate strength. Floors, on the other hand, will require thicker aluminum. Depending on your load-bearing needs, for instance, floor sheets will range between 0.063-0.125 inches in thickness.

Comparatively, for stainless steel thickness, 22 gauge offers moldability and structural integrity. From food handling to architectural features, 22 gauge stainless steel also comes in a variety of textures. Because of this, the different finishes let you curate the aesthetic of your space. For stainless steal floors, choosing either 18 or 16 gauge will provide the support for heavy loads.

Diamond Plates and Walk-In Coolers and Freezers

Overall, diamond plate tread offers structural integrity, slip resistance, and aesthetic appeal. Specifically, the diamond tread can be a practical choice for flooring or wainscotting in walk-in coolers and freezers. With Arctic Industries, you can fully customize your walk-in. From dimensions to color to diamond plated finish, each walk-in is specifically tailored to each client’s need. Take a virtual tour to start visualizing your new cooler or freezer.

[Featured image by Tim Mossholder on Unsplash]